|

The hydroblast system consists of a computer controlled robot, an ultra-high pressure pump, and a pneumatic vacuum conveyance system. The robot is designed to strip rail tank cars of any length ranging from 90 to 120 inches in diameter. The robot can pass through manways as small as 17 inches diameter. The robot is constructed of stainless steel and aluminum weighing approximately 1,000 pounds. The system is fully automated requiring no operator input during the hydroblasting operation. The robot controls the positioning and movement of an ultra-high pressure spinning nozzle to cut lining material and adhesive from the interior tank walls leaving a bare steel surface. Nozzle movement is computer controlled to maintain the maximum cutting rate achievable by the nozzle with the spray water volume and pressure supplied. The cut particles and spray water are lifted from the tank car by a pneumatic vacuum system and are deposited in a drainage bag. The solid materials are captured within the bag and the water is discharged free of suspended solids. A 20,000 gallon rail tank car is typically stripped in 6.5 hours of hydroblasting using 10 gpm at 38 kpsi. The captured solids are bagged, drained, and ready for hauling when hydroblasting is complete. The typical 20,000 gallon rail tank car has a turnaround time of 8 hours for the entire process using 5,500 gallons of water and 1,700 kWh of energy. |

|

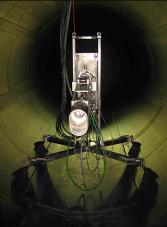

Robot Front View Inside Tank Car |

|

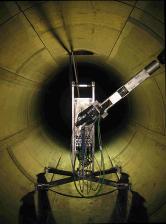

Robot Rear View Inside Tank Car |

|

Robot At Tank Head Ready to Blast |

|

Robot Arm Blasting 10 gpm @ 40 kpsi |

|

Robot Arm Rotating in Tank Car |

|

McWhorter & Associates, Inc. |

|

Robotic Tools for Rail Tank Cars and Tanker Trucks |

|

Rail Tank Car Lining Removal |

|

33 Bull Street, Suite 500, Savannah, GA 31401 USA • Phone 912-234-8891 • Fax 912-234-8892 • info@tankcarrobot.com |

|

Robot Side View |